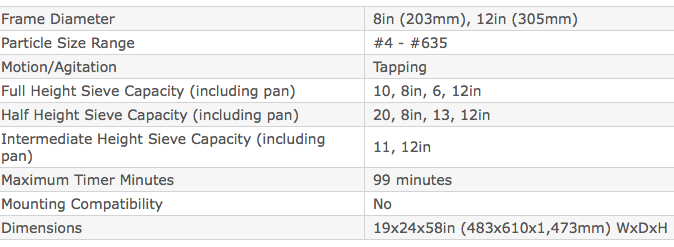

Gilson’s progressive design carries forward the best features of traditional rotary sifters and adds upgrades drawn from our expertise in particle separation technology. Faster conversion from 8—12in or 200—300mm diameter sieves, easier set up, and quieter operation all reflect the time devoted to improved design and materials. Sieve stack capacity ranges from six 12in diameter full-height sieves with pan, or up to twenty 8in diameter half-height sieves with pan.

The totally enclosed design allows safe, dust-free operation. The assembled sieve stack is simply placed inside and the cabinet is rotated back against the stops, no clamping is required. An ergonomic knob allows easy rotation of the cabinet between the loading and testing postions. A drive roller system continuously rotates the sieve stack with particle separation assisted by tapping against the stack. The digital countdown timer with large LED display precisely times operation up to 99 minutes at ±1 second. A pause function and userselectable modes offer greater versatility. Settings are saved between cycles for precise repeatability and easy, one-button operation.

Hammer assemblies are 6061 aluminum alloy with Ultra High Molecular Weight (UHMW) Polyethylene heads. Rugged painted case is dense, impactresistant MDF board and is mounted on a sturdy, powder-coated ASTM A 513 heavy steel tubing stand. The roller system is driven by a dependable 1/3hp continuous-duty motor.

This proven sieving method preferred by many DOT’s is now available with our guaranteed quality and reliability.

Dimensions: 19x24x58in (483x610x1,473mm), WxDxH.

Electric: 115V/60Hz