Fast

Shipping

Quick,

Simple Ordering

Clear,

Upfront Pricing

Over 30,000

Happy Customers

Exceptional

Customer Service

Industry's Largest

Catalog

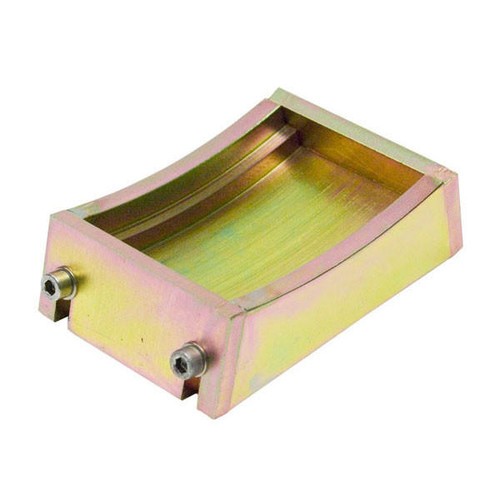

Specimen Mold for Accelerated Polishing Machine

The Specimen Mold for Accelerated Polishing Machine is an essential accessory designed for use with the Accelerated Polishing Machine. It plays a critical role in determining the wear resistance of aggregates under simulated road conditions, replicating the abrasive action of rubber tires. This mold is specifically engineered to prepare and shape aggregate specimens into 14 precisely curved segments, which are then clamped together for accurate and reliable testing. The mold ensures consistent specimen preparation, contributing to more dependable test results.

Crafted from durable machined metal, the Specimen Mold is built for long-term use and precision. It easily and securely attaches to the Mold Plate, ensuring a stable setup during the testing process. Whether you’re conducting routine quality control or in-depth research, this mold is a vital tool for evaluating aggregate performance in line with industry standards.

Key Features:

- Made of high-quality, machined metal for strength and durability.

- Precision-engineered to create 14 curved segments for accurate testing.

- Easily attaches to the Mold Plate for quick and secure setup.

- Designed for compatibility with the Accelerated Polishing Machine.

Applications: Ideal for laboratories conducting aggregate wear tests for road and pavement materials, ensuring that materials meet safety and durability requirements.

Meets Test Standards:

- AASHTO T279 (Accelerated Polishing of Aggregates)

- ASTM D3319 (Standard Test Method for Accelerated Polishing of Aggregates Using the British Wheel)

Specifications:

- Material: Machined metal

- Compatibility: Fits standard Mold Plates for Accelerated Polishing Machines

- Use: Preparation of aggregate specimens for wear resistance testing

Choose the Specimen Mold for reliable, efficient, and precise aggregate testing that meets industry standards.