Fast

Shipping

Quick,

Simple Ordering

Clear,

Upfront Pricing

Over 30,000

Happy Customers

Exceptional

Customer Service

Industry's Largest

Catalog

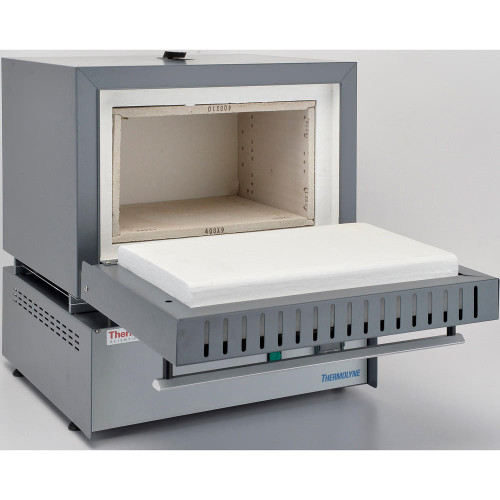

Thermolyne 2100C Furnace, Large Muffle, Max. Temp. 2192F, 14L

The programmable controller operates like single set-point controllers but can ramp up or down and dwell at constant temperature. It also has data acquisition for monitoring of processes and parameters. It has over-temperature protection. 2-ramp/2-dwell program capability and 0.3in (7.6mm) LED digital display in °C or °F.

Muffle Furnace 0.5ft³ (14.2L) capacity. Temp range 212-2192°F (100-1200°C). See our industrial furnace ovens and muffle furnaces for more options.

Large chamber with 4 heating on top, bottom and sides for uniform temperature. Rear of chamber has 0.31in (7.8mm) diameter port for temperature monitoring. When door is open, safety switch cuts power to heating elements.

Accessories:

-

Crucible Tongs to remove beakers and labware from furnace

-

Porcelain Crucibles for loss-on-ignition testing of cement, fly ash and soils. 10, 30 or 45mL

-

Heat Resistant Gloves for operator protection when placing or removing items in furnace

Capacity 0.5 cu.ft.

CSA approved

Description F6020C

Capacity 14 L

Temperature 100C to 1200C

Type Single Setpoint with Ramp and Programmable

Power 4400 w

Amps 18.3

Stability 0.3 at 1000C (2.2 at 1000C)

Dimensions (D x W x H) Interior 10 x12.8x 6.8 in. (25 x 33 x 18 cm)

Dimensions (L x W x H) Exterior 20.1 x 19.1 x 21in. (51 x 48.5 x 53.3 cm)

Electrical Requirements 240 50/60 Hz

Voltage 240 V

Frequency 50/60 Hz

Furnace Features

-

Furnace body: Double layer with observation window for safe and precise observation of melting process.

-

Vacuum gas system: 5x10^-3 Pa vacuum level for clean and controlled melting environment.

-

Power supply: Medium frequency 15KW max input power.

-

Heating element: Induction heating up to 2100°C.

-

Temperature control: PID control with precision +/- 1~5 ℃ (above 600 ℃)

-

Vacuum chamber: Water cooled crucible compatible. The vacuum chamber is connected to the water-cooled crucible and other system components to ensure seamless operation and integration.

-

Molecular vacuum pump system: FJ620 molecular vacuum pump with pumping rate (L/S) for air 600.

Safety and Control

-

Over temperature protection: Overheating protection.

-

Over current protection: Current protection.

-

Under pressure protection (water pressure): Protects the furnace from water pressure damage.

-

Broken even protection and display: Monitor furnace status and alert user to any error, continuous and safe operation.

-

Control system: Industrial monitoring system with 2 cameras and 1 industrial monitor for real time observation of melting process.

-

Mass flow controllers: Optional for gas system flow rate control, more versatile and precise.

Applications

-

Melting: Alloy steel, stainless steel, nickel based alloys, copper and other materials, precise temperature control.

-

Vacuum refining: Precise control of alloy composition.

-

Precision casting: High quality casting with precise temperature control, for various industries.

-

Research and development: Materials testing and analysis, for R&D projects.

-

Laboratory: Small batch processing and materials research, for laboratory use.

Power and Connection

-

Power supply: 3 PHASES, 240V, 50/60HZ, standard industrial power.

-

Input voltage: 3 PHASES, 240V, 50/60HZ, stable power.

-

Cooling water requirement: ≥0.2MPa water pressure.

-

Water pressure: 0.1-0.2 MPa.

-

Cooling water temperature: ≤25℃ to prevent overheating.

-

Environment temperature: 0~40℃.

-

Starting pressure: < 100Pa

Heating Type

At the heart of Thermolyne 2100C Furnace is the medium frequency heating technology, which provides fast and uniform heating throughout the chamber. Multiple heating elements including high performance graphite hot zones are strategically located to maintain constant temperature and excellent temperature uniformity. The control system controls these heating elements and includes protection and water pressure monitoring. The chamber further improves performance by removing moisture and contaminants, extending the life of the heating elements and ensuring consistent results. This combination of controlled heating and protection system can handle various thermal processes with reliability and efficiency.

Configurations and Options

Thermolyne 2100C Furnace has various configurations to suit different application needs. Users can choose different hot zone materials, tungsten or graphite, to optimize performance for specific process. Optional mass flow controllers provide precise gas flow rate control, and integrated system supports various gases, nitrogen and hydrogen, for special atmosphere. The control system is user friendly with digital display and interface that simplifies operation and monitoring. Built-in data acquisition system allows tracking and recording of key parameters such as temperature and pressure for process optimization and quality assurance. These options and controls make the furnace adaptable to wide range of research and industrial applications.

Applications and Use Cases

Thermolyne 2100C Furnace is designed to be versatile, suitable for laboratory research to industrial processing. 14L chamber is perfect for small batch processing, melting, sintering and treating metals, alloys, ceramics and other materials. Vacuum and gas system allows controlled atmosphere, induction melting and vacuum melting where environmental control is critical. Over temperature protection, pressure protection, over current protection ensure safe and reliable operation even during harsh process. For those seeking alternative solutions for similar laboratory needs, the Thermolyne FB1410M Muffle Furnace is another reliable option. Whether for quality control, research and development or special material processing, Thermolyne 2100C Furnace can deliver consistent results across wide range of temperature, pressure and material.