Fast

Shipping

Quick,

Simple Ordering

Clear,

Upfront Pricing

Over 30,000

Happy Customers

Exceptional

Customer Service

Industry's Largest

Catalog

F.A.P. Plus ZW Pneumatic Overfill Protection System for 1 to 5 Pumps

An overfill prevention system is a must have for safe and efficient tank and terminal operations. The main function of such a system is to prevent overfilling which can cause spills, environmental damage and big losses. Overfill prevention systems are designed to detect when a tank is near full and automatically shut off the filling process so overfills are prevented. These systems are required for industries that handle liquids such as oil, gas and chemicals. By having an overfill prevention system companies can minimize accidents, reduce costs of cleanup and repair and comply with regulations.

TR-75713 DGSI F.A.P. Plus ZW Pneumatic Overfill Protection Device for 1 to 5 pumps | DGSI Slope Indicator Environmental Products

This is part of our full line of products and overfill prevention solutions for tank overfill protection. The right parts and accessories are key to the overfill protection solutions during loading operations, so overfill protection is effective. It is installed on the recovery tank or drum to overfilling of the product storage vessel and environmental damage. Main air is supplied to the inlet side of the overfill device and outlet air to the F.A.P. Plus ZW pump. Overfill device is triggered by increased fluid levels in the recovery tank and off air supply to the F.A.P. Plus ZW pump.

Our industry leading expertise and overfill prevention technology has the highest level of safety and compliance. Overfill prevention is key to operational safety and regulatory compliance. That means compliance with regulations and prevention of environmental damage. Standard overfill device can be used with up to 5 pumps and installs into a standard 2-in bung.

Tank Overfill Protection Systems

Tank overfill protection systems are for keeping overfilling of storage tanks which can cause severe consequences such as spills, fires and environmental damage. These systems are critical for safe and efficient operation of storage tanks across many industries including hazardous materials, oil and gas, chemical and food processing. A typical tank overfill protection system is a combination of sensors, monitors, control devices and automatic turn-off valves that work together to detect and keeping from overfilling. By monitoring the liquid level in the tank these systems can turn off the flow of liquid when a high level is detected and prevent the hazard. Overflow sensors work alongside other safety devices to detect high levels in tanks and issue alerts, so operations are safe and efficient.

DGSI F.A.P. Plus ZW Pneumatic Overfill Protection Device

The DGSI F.A.P. Plus ZW Pneumatic Overfill Protection Device is a simple and effective solution for overfill prevention. This device provides high level of protection against overfilling to protect people, equipment and the environment. The F.A.P. Plus ZW is a pneumatic device that uses a float activated valve to shut off the flow of liquid when the tank reaches a certain level. It can be used in many applications including storage tanks, fuel tanks and tanker trailers. This device is ideal for these applications because it prevents overfills. By using this technology operators can reduce the risk of spills and hazards and operate safely and compliant.

How it Works

The overfill prevention system works by using sensors and monitors to detect the level of liquid in a tank. These sensors can be installed in various configurations, top loading and bottom loading setups, to ensure accurate and reliable monitoring. When the liquid level reaches a predetermined point the system sends a signal to stop the filling process so overfilling and potential spillage is prevented. The system can be designed to accommodate various types of tanks and terminals, large storage facilities and smaller transportation vehicles. By providing real time monitoring and automatic shutdown capabilities overfill prevention systems are a proven solution for overfills and safe and efficient operations.

Application:

This pneumatic device is activated by a high liquid level in the fuel recovery tank. Once activated it shuts off the air supply to the pneumatic pump and stops fluid discharge to the tank, so operators are alerted to stop filling to prevent overfilling. Overfilling of fuel tanks and tanker trailers is a big risk, potential dangers, liabilities and operational challenges.

Applications and IndustriesTank overfill protection systems are used in:

-

Oil and gas

-

Chemical processing

-

Food and beverage

-

Pharmaceutical

-

Transportation

These systems are for protecting storage tanks, fuel tanks and tanker trailers from overfilling which can cause spills, fires and other hazards. Overfill prevention is also critical in industries where overfilling is high risk such as in transportation of hazardous materials. These systems ensure safety during the transport of cargo by preventing hazardous spills and protecting both the vehicles and the cargo being transported. By using these protection systems companies can operate safely, minimize environmental impact and comply with strict regulations.

Features and Benefits

Tank overfill protection systems have many advanced features and benefits to maintain safety and efficiency. Features include:

F.A.P. Plus™ Pump System for Prevention

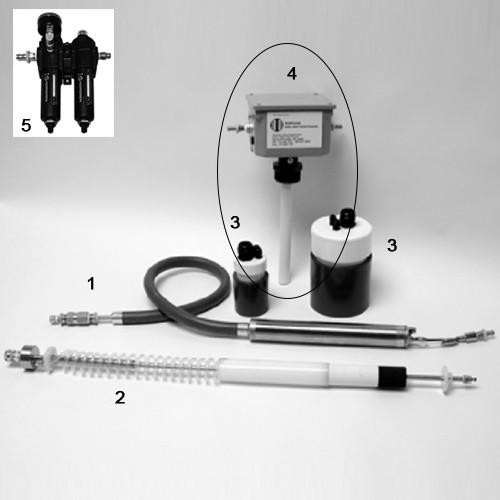

The F.A.P. Plus™ Pump system is a complete overfill protection solution and consists of 7 components: built for durability and integrated functionalities:

-

F.A.P. Plus™ Pump (1*)

-

Skimmer Assembly (2*)

-

Well Clincher (3*)

-

Filter/Regulator (5*)

-

Pneumatic Overfill Protection Device (*)

-

Electric Air Compressor (not shown*)

-

Hoses (not shown*)* refer to product photo for reference

Options:

-

Solar NAPL Compressor

-

F.A.P. HF

Specifications For TR-75713 Pneumatic Tank-Full Shut-Off and Tank Overfill Protection Systems

-

6 x 6 x 21 in

-

Weight: 4lb

-

Enclosure: PVC and 6061 aluminum

-

Chemical Compatibility, Exterior Components: Refined petroleum products

-

Compressed Gas Supply: 0 to 100 psi, filtered to 40 microns (see note 1). Providing detailed product information ensures users understand the specifications and proper usage.

-

Compressed Gas Consumption: 0 scfm

-

Control Valve: 2 way, normally open, 20 scfm @ 100 psi (see note 2)

-

Operating Temperature: 33 to 120°F. (see note 3)

-

Compressed Gas Connections: Primary ¼” O.D. push-to-connect tubing fittings. Secondary ¼” female NPT on bulk heads

-

Status Indicator: Pressure indicator colorimetric, “Green” compressed gas is supplied to pumps, “Black” compressed gas is off to pump(s)

-

Reset: Manually operated

Note 1: Synthetic oil in an air compressor can cause chemical deterioration of components in the Control Valve and result in unit failure.

Note 2: The TR- 75713 can support up to six FAP+ZW skimmer pumps. Contact a factory representative before using more.

Note 3: If the unit must be operated below 33°F., a desiccant air dryer must be used to reduce the dew point of the moisture in the compressed gas to a lower temperature than ambient. If using inert compressed gas, check with the supplier to see what the dew point temperature of the inert gas is.

Installation and Maintenance

Proper installation and maintenance is crucial for tank overfill protection systems. Installation should be done by qualified personnel with experience in these types of systems to ensure all components are properly set up and working. Maintenance is just as important and should include checking sensors and monitoring systems for proper function and calibration, testing automatic shut-off valves to see if they work, and checking alarms and notifications. Routine software updates and backups are also necessary to keep the system running. Documenting all maintenance and keeping a record of system performance will help you identify potential problems early and ensure long term protection system reliability.