• Meets current standards, including more stringent Texas DOT requirements.

• Multi-function electronic controller tracks time, speed, and total revolutions.

• Easier, safer, and less expensive to operate.

• Lexan doors and safety interlocks insure no exposed moving parts.

The increasingly popular Micro-Deval Apparatus measures abrasion resistance and durability of mineral aggregates in the 9.5 to 19mm size range. An aggregate sample is placed in a sealed stainless steel jar with a 5000g abrasive charge of 9.5mm diameter stainless steel balls and water, then rotated at 100 rpm for two hours. Aggregate quality is determined by percentage loss in gradation results at completion. Smaller equipment size, lower sample quantities and a simpler procedure make the method easier and less costly to perform than traditional methods.

The Micro-Deval Apparatus meets current Canadian ASTM and AASHTO standards, as well as more stringent Texas DOT requirements. This contemporary version of the Micro-Deval test should not be confused with older versions originating in Europe which use different equipment and test protocol. This model is a second generation, state-of-the-art machine. A sophisticated electronic controller with optical sensing system accurately tracks test time, total revolutions and rpm of jars. Test duration may be controlled by either elapsed time or total revolutions. Jars stop within a fraction of one revolution at test termination. Jar revolution and speed data may also be used as a verification of machine performance.

The jars revolve behind closed Lexan™ doors with safety interlocks. No moving parts are exposed during operation. Other manufacturers use separate timers to control test duration, which does not permit tracking of jar revolutions or speed and allows variations up to ±6% of the optimum number of revolutions. In addition, other machines spin the jars on unguarded open rollers, creating a potentially hazardous situation.

The MicMicro-Deval Apparatus machine is a two-tier unit with sturdy steel frame. Each tier carries one stainless steel 5 liter jar, 194mm ID, 170mm internal height with locking cover. Power to the rubber-covered rollers is supplied by a 3/4-HP, 115V, 60Hz electric motor through a gear transmission and chain drive. The unit is supplied with two jars and two 5500g abrasive charges. A magnet is included to assist in removing the abrasive charge after the test is complete.

Overall dimensions are 20.5x13.5x38" (521x343x965mm).

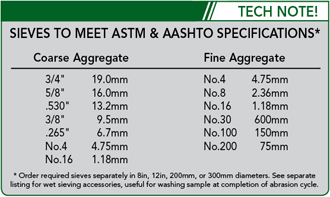

Sieves required for this test include: 3/4" (19.0mm), 5/8" (16.0mm), .530" (13.2mm), 3/8" (9.5mm), .265" (6.7mm), No. 4 (4.75mm), and No. 16 (1.18mm). Order separately in 8", 12" or 200mm diameters sieves.

Electric: 115V/60Hz 3/4HP

Meets Test Methods:

AASHTO T327

ASTM D 6928

ASTM D 7428

ONTARIO LS-618

TxDOT 845-49-40