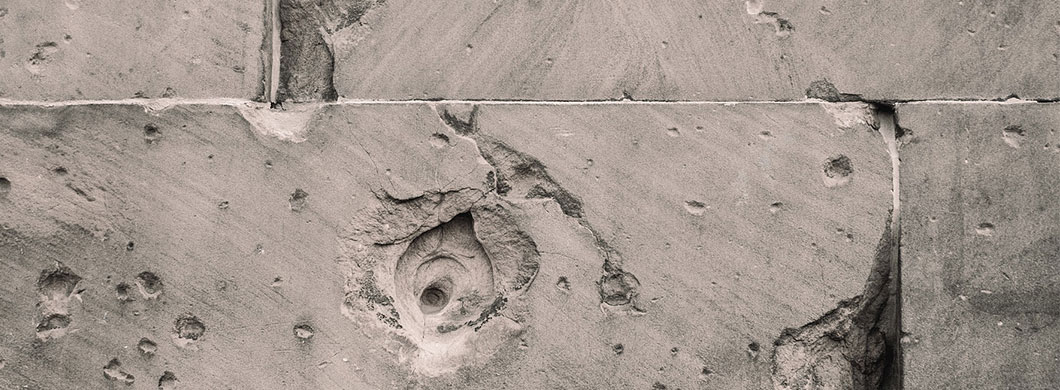

Why Concrete Testing Matters in Construction

Posted by Certified Material Testing Products on Nov 03, 2014

The Certified Material Testing Products experts love giving advice and helpful information to our customers and prospective customers. The importance of concrete testing is lost on some and understood by few in the materials testing world. We're here to give some helpful information and advice.

Firstly, it's important to know why: concrete is tested to ensure that the material that was specified and bought is the same material that was delivered to you or the job site. There are a dozen of test methods for freshly mixed concrete, as well as at least another dozen for hardened concrete. Slump, air content, unit weight, and compressive strength tests are the most common tests.

To go into further detail...

Slump tests measure the relative ability of the concrete to flow. If your concrete can't flow because the slump is too low, you're potentially going to have problems with proper consolidation. If the slump is too high and your concrete doesn't stop flowing, you may experience mortar loss, formwork pressures, finishing delays, and segregation.

Testing for air content measures just that, the total air content in fresh concrete. However, it doesn't indicate what the final in-place air content will be.

Your unit weight test will measure the weight of your sample of concrete.

Compressive strength tests are conducted by pouring a cylinder of fresh concrete and measuring the force needed to break the concrete cylinder. Normally, as long as no single test is more than 500 psi below the design strength, then the concrete is acceptable. 8