Air and Concrete: How Much Should They Mix?

Sep 10, 2018

The air entrainment process is a crucial for creating strong concrete that can weather the elements. As such, the concrete air test is just as necessary as other common strength and slump tests. Before we get into how to perform a concrete air entrainment test, we should be familiar with what air entrainment is.

What Is Air Entrainment?

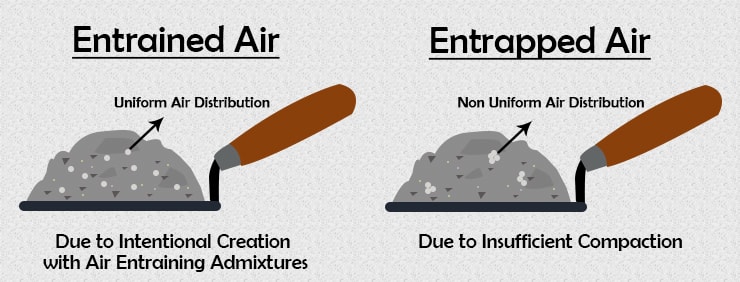

Air entrainment describes the process of introducing air entraining agents into concrete paste, or using cement that is already air entrained. Billions of microscopic air bubbles fill each cubic foot of the concrete to relieve internal pressure during freeze/thaw cycles.

Why Is Air Entrainment Necessary?

Entrained air pockets act as tiny chambers for water within the concrete to expand as it freezes, which helps reduce the risk of scaling and other common issues.New concrete in particular will benefit, as it is the most likely to have a high moisture content and have not yet cured completely to reach its full strength.

Air entrainment in concrete is especially important where salt and deicers will be used, even deicers that are not corrosive. These kinds of chemicals can be hard on concrete because they lower the freezing point of water, which thaws existing ice, but the will often refreeze when the temperature drops below that new freezing point. . The result is even more freeze/thaw cycles.

Having the proper air entrainment ratio can help contain the damage caused by natural freeze/thaw cycles as well as those caused by people fighting ice in the wintertime.

Is There a Golden Ratio?

As with all other aspects of mixing strong concrete, there is an air entrainment window you should aim for. Entrained air should fall between 4% and 7% of the concrete's volume. For concrete that will be regularly exposed to freeze/thaw cycles, aim for 6%. Anything less than 4% would not have the durability needed to last through multiple winters.

Be careful not to go overboard with air entrainment, however. Having too much air in your concrete can reduce its strength — for every percent increase in air entrainment, compressive strength can be reduced by 2% to 6%. Performing concrete air entrainment testing will help you find the perfect air volume for your mixture.

How to Perform a Concrete Air Entrainment Test

Concrete air entrainment testing is typically performed on plastic, or fresh, concrete. Pressure method ASTM C 231 is the preferred test for determining air void spacing and volume in concrete. In order to perform the pressure test, you will need an air entrainment meter capable of performing Type B or SAM tests. A good air entrainment meter will produce results within ±1% of target value in about 10 - 15 minutes. If results fall outside of the 4% to 7% range, the volume of air entrainment will either need to be increased or decreased to ensure the final product has good compressive strength and freeze/thaw resistance.

Find High-Quality Air Entrainment for Concrete Equipment At Certified MTP

At Certified Material Testing Products, we offer the latest and greatest concrete air entrainment meters available, ensuring that your concrete has the proper strength and durability. For other concrete testing equipment, visit our full catalog of meters, accessories and more. We offer our best so that you can do your best, no matter the project.